PVD and Electroplating: Current Trends and Future Scenarios for Metal Finishes

The Macro-Trend in Surface Finishes

In 2026, surface finishing is a fully-fledged design element. It no longer responds solely to decorative logic but integrates aesthetics, functionality, and durability, becoming a key lever for product positioning. In sectors such as fashion, accessories, eyewear, furniture, and design, the metallic surface is now part of the brand language.

The current scenario is characterized by surfaces that are more textural (materic), less reflective, and technically high-performing. Looking at the evolution over the next few years, a clear direction emerges: consistent finishes that are stable over time and designed for longer lifecycles. In this context, PVD and electroplating do not compete, but integrate to meet increasingly specific needs.

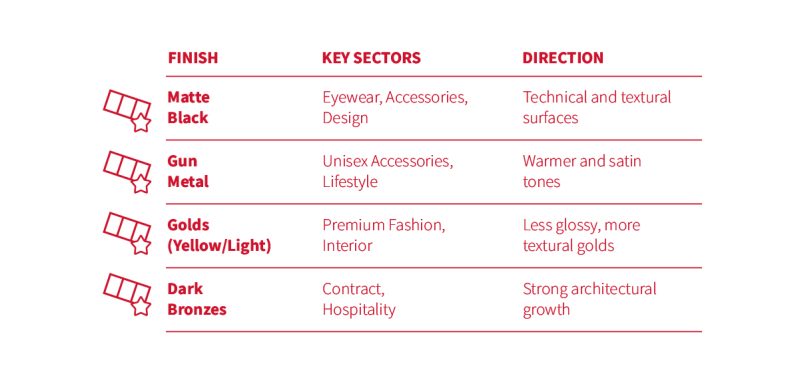

The Most Relevant Finishes Today

Matte Black and Deep Black: The Contemporary Standard

Black represents the most transversal and consolidated finish today. Matte, super-matte, and velvety black have become a standard in contemporary design, especially for products focusing on minimalism, precision, and technology.

It is widely used in luxury eyewear, essential fashion accessories, door hardware, and design components. PVD Black stands out for its compact, metallic yield, capable of conveying quality to the touch as well as the eye. Compared to painted coatings, it offers greater wear resistance and superior color stability, central aspects for products subject to daily use. Sandblasted and micro-matte textures further reinforce the technical character of the surface, responding to a growing demand for finishes that are less sensitive to signs of aging.

Gun Metal: Evolved Neutrality

Gun metal is one of the most appreciated finishes for its sophisticated neutrality. It is not a protagonist color, but a solid base that adapts to very diverse contexts, from fashion accessories to lifestyle products and functional design.

Today, it is chosen primarily in fine-satin versions, with a slightly warmer tone compared to past interpretations. This evolution makes it suitable for women’s collections and premium products seeking visual balance without sacrificing character.

From a technical standpoint, PVD allows for uniform and stable surfaces capable of masking micro-scratches and maintaining high aesthetic quality over time, an increasingly relevant aspect in durability-oriented design.

Yellow and Light Golds: Value, Substance, and Sobriety

Among the most relevant finishes of the present are yellow gold and its lighter variants, reinterpreted in a contemporary key. Excessively glossy surfaces give way to satin and lightly brushed textures, which express value without ostentation.

LEM uses 100% recycled gold compliant with RJC standards, guaranteeing sustainability, traceability, and quality. This approach allows the intrinsic value of the metal to be combined with environmental responsibility, aspects that are increasingly relevant for high-end brands.

Palladium and Ruthenium: Continuity and Reliability

Palladium and ruthenium confirm themselves as stable finishes in the contemporary luxury landscape. Their sophisticated and neutral tone responds to a constant demand for discreet elegance, far from seasonal fads. They are particularly requested in contemporary jewelry, design lighting, and men’s accessories.

Dark Bronzes and Warm Finishes: Identity in the Contract Sector

In the furniture and hospitality worlds, warm finishes continue to gain ground. Dark bronzes, often identified by commercial names like Cortìn, are now a widespread choice for contract projects focusing on welcome, solidity, and character.

These surfaces introduce a textural component that balances minimal environments and dialogues with wood, stone, and natural fabrics. They are used in door hardware, design faucets, and architectural elements, with a growing preference for satin versions, which are more suitable for high-traffic contexts.

Rose Gold: Balance and Recognizability

Rose gold maintains a constant presence as an elegant and recognizable finish. Today it is used in a controlled manner, especially in fashion accessories and decorative details, with a preference for satin surfaces and balanced tones.

Vintage Finishes: Character, Authenticity, and Quality Control

Alongside cleaner, contemporary surfaces, there is growing interest in finishes with a “lived-in” aesthetic. LEM’s Vintage finish interprets this trend with a controlled, sophisticated, and repeatable aged effect, designed for high-end brands seeking differentiation and storytelling.

The vintage effect is not random, but the result of a controlled galvanic process that ensures high durability, compatibility with different materials and surfaces, and compliance with major environmental and safety standards. The ability to produce the finish in a Nickel Free version also makes it suitable for products intended for skin contact, expanding its applications in fashion and accessories.

Metal Finishes: 2026 Trends

Texture and Technology: The Heart of Future Evolutions

The evolution of finishes concerns not only color but how the surface is designed. Current trends and future forecasts converge on key points:

- Reduction of gloss/brilliance;

- Greater material depth;

- Better wear tolerance.

Glossy surfaces remain present for iconic products, but satin, matte, and sandblasted finishes are destined to grow further.

In this scenario, the integration between electroplating and PVD allows for the combination of aesthetic value, substrate uniformity, and surface protection, offering tailored solutions for increasingly long lifecycles.It is within this logic that LEM’s integrated approach fits, combining galvanic and PVD expertise to support designers and manufacturers in choosing the most effective solution, today and for years to come.

FAQ – Metal Finishes, PVD, and Electroplating

Which finishes are most requested today?

Matte black, satin gun metal, textural yellow golds, and warm dark bronzes are the most widespread finishes in the main design-driven sectors.

Which types of finishes will grow in the coming years?

Opaque and satin surfaces, stable and non-seasonal colors, and finishes designed to last and age well.

Is texture really that important?

Yes. Texture influences visual perception, touch (haptics), and the surface’s ability to maintain aesthetic quality over time.

Francesco

Responsabile Commerciale - LEM srl

Did you find the article interesting? Share it now.

© 2026 Lem Galvanica. All rights reserved

Did you find something interesting? Contact us now!

LEM technicians are ready to address any questions or concerns you may have.

Request more information and discover our tailor-made solutions.

Other articles you may be interested in

Gold PVD: characteristics, performance and tones of the surface treatment

Gold PVD: durability, colors, rose gold and yellow gold, use on steel and why it does not wear easily. Complete guide to gold PVD treatments.

Water management and treatment in electroplating and PVD: what really happens behind the scenes

Wastewater treatment and recirculation in electroplating and PVD: technologies, green chemistry, and solutions to reduce waste, costs, and environmental impacts.

PVD (Physical Vapor Deposition): definition, operation and main applications

The PVD process, Physical Vapour Deposition. A technical overview of how it works, the materials involved, and its industrial applications.