Outsourcing PVD and Galvanic Treatments: Advantages, Risks, and Strategies in Industrial Subcontracting

A strategic choice for Italian industry

In the surface treatment industry, deciding whether to manage a galvanic or PVD plant internally or rely on a specialized external partner is a strategic turning point for many companies.

Is it more convenient to set up an in-house production line or to work with a galvanic and PVD subcontractor capable of ensuring quality and continuity?

Today, key sectors of Italian industry, including tapware, furniture, fashion, eyewear, and automotive, face this very dilemma.

Galvanic and Physical Vapor Deposition (PVD) technologies require advanced technical expertise, significant investments, and constant updates on regulations and safety. In a context where aesthetic standards, environmental constraints, and market demands evolve rapidly, the choice of the organizational model can deeply affect competitiveness and sustainability.

The goal of this article is to concretely analyze the advantages and challenges of outsourcing galvanic and PVD processes versus in-house management, evaluating their technical, economic, and organizational impacts.

Investment and Operating Costs: The Weight of the In-House Plant

When a company decides to install an in-house galvanic or PVD plant, the first barrier is cost.

Purchasing and commissioning such a system requires a very high initial investment, which can reach millions of euros just for equipment: vacuum chambers, suction and filtration systems, galvanic tanks, purification circuits, safety devices, and disposal systems.

Recurring Operating Costs

To these initial costs must be added the ongoing expenses, often underestimated but equally significant:

- Electricity (particularly high for PVD processes involving vacuum and evaporation or sputtering)

- Consumables and chemical products

- Maintenance and waste management

- Qualified technical staff

- Machine downtime and periodic environmental controls

For many companies, especially those with variable production batches or special finishes, these fixed costs become an obstacle to competitiveness.

The plant must operate continuously to amortize the investment, but in periods of lower demand it risks remaining underused, increasing the unit cost per piece.

The Advantage of an External Partner

Relying on a galvanic and PVD subcontractor allows these fixed costs to become variable: you pay only for the treatments actually performed, without immobilizing capital or bearing the risks of plant downtime.

The external partner takes on the burdens and responsibilities, allowing the company to focus its resources on product development, design, and innovation.

A practical example: a tapware or furniture manufacturer wishing to introduce a PVD finish such as satin copper or polished gold would face high costs and uncertain returns. By outsourcing instead, they access the same quality while paying only for what they produce, gaining flexibility and reducing financial risk.

Summary

Outsourcing galvanic and PVD treatments lightens the company’s structure, reduces risk, and allows energies to be focused on innovation and product value instead of plant management.

Regulations and Chemical Safety: Managing Complexity

Running an in-house galvanic or PVD department also means handling one of the most regulation-heavy areas in manufacturing.

Companies must ensure compliance with REACH, RoHS, and IED (Industrial Emission Directive) standards, implement safety plans for personnel, and properly manage waste and discharges. This requires specific technical expertise and often a dedicated internal compliance department.

Traditional galvanic processes involve managing electrolytic baths, heavy metals, acidity, toxic substances, neutralization, and waste disposal, all under frequent inspections.

PVD processes, on the other hand, require managing vacuum chambers, evacuation systems, waste discharge, high-energy equipment, and complex technologies.

When finishing work is entrusted to an external galvanic and PVD partner, it is that partner who takes care of:

- Monitoring environmental and safety parameters

- Updating procedures according to new EU directives

- Ensuring process traceability and consistent quality

This allows the client company to stay focused on its core business while reducing operational and legal risks.

Summary

In-house management of galvanic or PVD systems involves high regulatory complexity. Working with a certified subcontractor reduces risk and burden, ensuring safety, compliance, and consistent process quality.

Technology and Know-How: Staying Up-to-Date Takes Time (and Capital)

The surface treatment industry evolves quickly. New formulations, trend colors, and complex substrates demand constant updates on both technical and regulatory fronts.

Keeping an internal plant updated requires continuous Investment and running an in-house galvanic or PVD plant means constantly investing in:

- Software updates and process control systems

- Staff training

- Research on new materials and deposition cycles

Even an efficient plant can become obsolete within a few years, compromising finish quality and the company’s responsiveness to market trends.

The Competitive Edge of Specialized Suppliers

A specialized galvanic and PVD partner invests regularly in technology, experiments with new finishes, and continuously updates its offer.

This allows clients to access up-to-date know-how without immobilizing capital or slowing down production.

For example, a design-oriented company can quickly introduce a new PVD finish such as “carbon black” or “champagne satin” without purchasing new targets or conducting internal tests.

Summary

Outsourcing transforms technological complexity into a competitive advantage, letting the partner keep the “machine” constantly updated.

Production Flexibility and Reduced Downtime

One of the main limits of an internal plant is operational rigidity. Every color, formula, or material change requires setup times, compatibility tests, and line stoppages. For companies working on multiple collections or variable orders, this can mean delays, added costs, and inefficiencies in planning.

When galvanic or PVD processes are managed internally, downtime must also be considered for maintenance, process checks, production changes, or unexpected failures. In low-demand periods, the plant remains idle but continues generating fixed personnel and energy costs.

Outsourcing to Increase Flexibility

Working with an external partner allows faster adaptation to market rhythms.

The company can send components for treatment only when needed, avoiding waste and maintaining steady production capacity.

The supplier manages loads, finish changes, and setup times, ensuring continuity and on-time delivery.

This model is particularly useful for companies handling variable batches, small series, or prototypes, or those that need to quickly respond to new color and finish demands.

Main benefits

- Reduced downtime and inactivity

- Faster color or substrate changes

- Cost optimization based on actual volumes

- Immediate response to demand peaks or product launches

Summary

Outsourcing galvanic and PVD treatments makes production more agile, scalable, and predictable, reducing waste and inefficiency. It means shifting from a rigid internal logic to a dynamic, adaptive model that ensures production continuity, faster lead times, and lower economic exposure during market slowdowns.

Experimentation and Prototyping: Innovate Without Immobilizing Capital

In today’s industrial landscape, aesthetic and functional innovation is a key competitive factor.

In sectors such as tapware, bathroom furnishings, fashion accessories, eyewear, and automotive, the ability to offer special finishes, exclusive colors, and high-performance textures represents a real market advantage.

The limits of internal plants

For companies with in-house galvanic or PVD systems, each new finish requires long and costly testing phases: adhesion tests, parameter calibration, material consumption, and technical staff hours.

Each experiment thus becomes an investment in time, resources, and risk, often unsustainable if the finish is not later used in production.

Experimenting with an external galvanic and PVD partner

Collaborating with a specialized supplier allows access to a fully equipped lab for testing and rapid prototyping.

The partner can produce small batches or pre-series samples, test aesthetic and mechanical performance, and support the company in choosing the best substrate–finish combination.

This approach encourages continuous innovation: the client can introduce new collections or update product lines without immobilizing capital or halting ordinary production.

Practical example: a furniture or fashion brand can quickly test a new PVD finish like “satin rose gold” or “dark titanium,” verify its aesthetic and resistance performance, and launch it on the market in reduced time with minimal testing costs.

Summary

Outsourcing experimentation enables fast and safe innovation while reducing costs and risks.

The PVD and galvanic partner becomes a strategic ally in developing high-end finishes, ensuring reliable results and market competitiveness.

When does it make sense to manage an in-house galvanic or PVD plant?

Of course, there’s no one-size-fits-all solution. Outsourcing offers clear advantages, but in some cases, in-house management may be more efficient.

Companies with very high production volumes, standardized finishes, and well-established processes can quickly amortize their investment while maintaining direct control over timing, quality, and logistics.

In-house management makes sense when:

- Production is continuous and predictable

- The required finishes are always the same

- The company has internal technical expertise and trained personnel

- There is a desire to fully integrate the production cycle

In these cases, fixed costs are offset by economies of scale, and internal management allows full confidentiality over processes and finish recipes.

However, even this choice requires constant investment in technology, safety, and regulatory compliance to avoid plant obsolescence.

The hybrid model: a growing balance

For many Italian companies, especially in design and furniture sectors, the ideal solution is a hybrid one: keeping some strategic phases in-house, such as preparation, quality control, or color management, and outsourcing special or niche finishes to certified partners.

This model combines the best of both worlds:

- Internal control and expertise over key phases

- Flexibility and innovation guaranteed by the subcontractor

This way, companies can optimize costs, reduce risks, and maintain the ability to innovate, adapting production to market needs.

Summary

An in-house plant is logical only for companies with high, stable volumes; for most Italian businesses, galvanic and PVD subcontracting, or a hybrid model, offers a more sustainable balance between efficiency, innovation, and control.

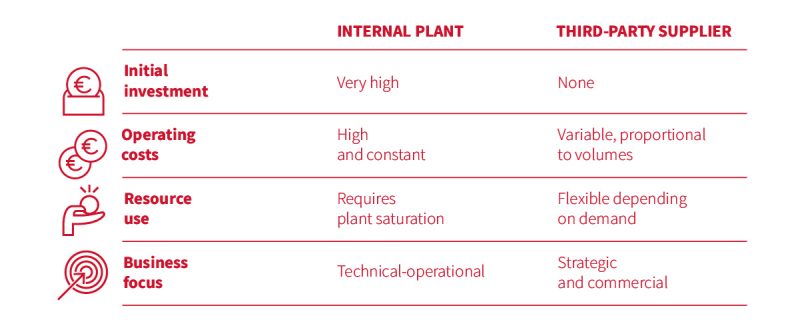

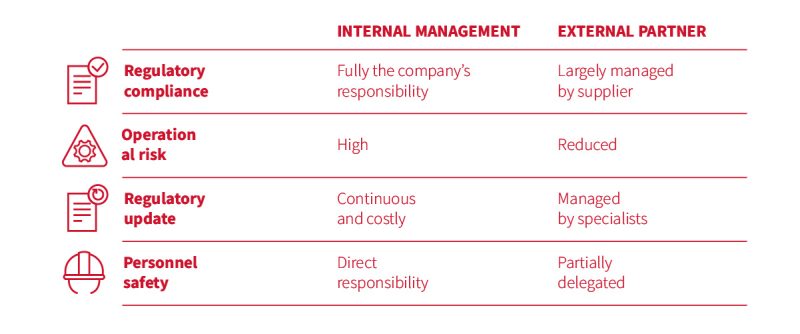

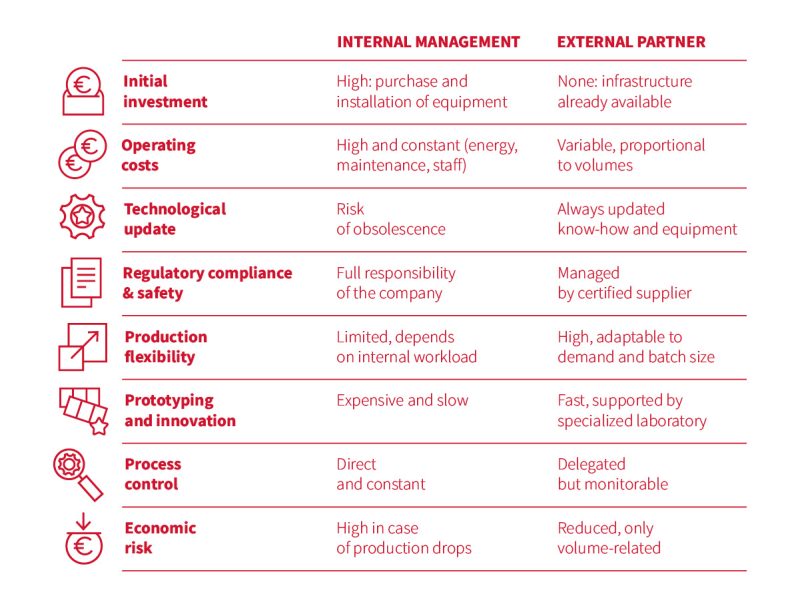

Comparative summary: In-House vs. Specialized Partner

After analyzing the advantages and limitations of both options, it is useful to directly compare the main factors that influence the choice between an in-house system and an external company.

The comparison highlights that for most Italian companies, working with a specialized galvanic and PVD subcontractor provides greater flexibility and access to updated expertise with a more balanced financial commitment.

Summary

The in-house model ensures control but requires resources and production stability; industrial subcontracting, on the other hand, offers agility, economic sustainability, and continuous innovation, making it the most suitable solution for companies seeking growth without immobilizing capital.

LEM as a Partner for Galvanic and PVD Treatments

In this context, a company specialized in galvanic and PVD processes such as LEM acts as a partner capable of managing the entire finishing cycle, from part preparation, galvanic treatment, and PVD coating, to quality control, logistics, and finish confidentiality.

This allows the client to focus on design, product, and market, leaving the “treatment machine” in the hands of experts: the company keeps only strategic key phases in-house while delegating flexible, technology-intensive, and capital-heavy finishing processes to the subcontractor.

The result: high quality, process control, and flexibility, without the burden of fixed costs or immobilized capital.

Summary

Collaborating with LEM Galvanica PVD means having a technical and strategic partner capable of combining industrial precision, production flexibility, and continuous innovation, key elements for remaining competitive in a rapidly evolving market.

Conclusion: choosing the most efficient path

When comparing in-house management versus industrial subcontracting for galvanic and PVD treatments, the advantages of a specialized partner are clear:

- Reduced initial investment

- Greater production flexibility

- Lower technological and regulatory risk

- Immediate access to updated know-how

- The ability to test new finishes without immobilizing capital

Of course, in-house plants can be justified in specific cases: large volumes, stable processes, standardized finishes. However, for most Italian companies, particularly those focused on design, customization, and innovation, working with a qualified external galvanic and PVD supplier is the smartest and most sustainable choice.

If your company is evaluating how to organize its surface treatments, consider all the factors outlined here and choose the solution most aligned with your production model and strategic goals.

Discover how to optimize your PVD and galvanic treatments with LEM, a reliable, up-to-date, and technologically advanced partner supporting Italian industry.

Leonardo

Responsabile laboratorio chimico area galvanica - LEM srl

Did you find the article interesting? Share it now.

© 2026 Lem Galvanica. All rights reserved

Did you find something interesting? Contact us now!

LEM technicians are ready to address any questions or concerns you may have.

Request more information and discover our tailor-made solutions.

Other articles you may be interested in

How a PVD System Works: Technologies and Processes Explained

Discover how a PVD coating system works: vacuum chamber structure, deposition technologies (Sputtering, Arc), and process control. An industrial guide for companies.

PVD and Electroplating: Current Trends and Future Scenarios for Metal Finishes

Discover the latest metal finishes: matte black, gun metal, golds, and bronzes. Trends in PVD and electroplating for fashion, design, and contract sectors.

Gold PVD: characteristics, performance and tones of the surface treatment

Gold PVD: durability, colors, rose gold and yellow gold, use on steel and why it does not wear easily. Complete guide to gold PVD treatments.