Gold PVD: characteristics, performance and tones of the surface treatment

Gold finish by Physical Vapor Deposition

PVD is today one of the most widely used surface treatments in eyewear, fashion accessories, contemporary watchmaking, and metal small parts. In the case of gold PVD, the technology makes it possible to achieve a stable, bright, and repeatable gold-like effect, with superior resistance compared to traditional decorative processes. There is often confusion regarding this type of finish, as despite the name, a gold target is usually not used in the process.

Unlike electroplating, gold PVD does not always deposit real gold. At LEM, the gold PVD process is industrialized according to two distinct protocols to meet specific specification requirements:

- Ceramic film synthesis (simulated gold PVD): The creation of high-performance coatings based on metallic nitrides that provide very high surface hardness.

- Multilayer systems (gold PVD): A complex architecture that combines a simulated gold base layer for mechanical resistance with a final color layer in 24k gold, available in all the shades listed in the catalog, to ensure absolute chromatic fidelity of the precious metal.

What gold PVD is and why it is so in demand

Gold PVD finishes are considered a versatile and controllable solution. Thanks to the composition of the film, the coated surface features long-term color stability, good scratch resistance, and hypoallergenic properties. The process is also effective on different materials such as steel, brass, or zinc alloy (on the latter two, application is only possible after electroplating), ensuring a uniform final result.

How simulated gold PVD treatment works

The PVD treatment is carried out under high-vacuum conditions inside dedicated systems. The first step is the controlled vaporization of the target material: depending on the type of finish required, simulated gold or real gold, the process involves the evaporation of transition metals (such as titanium and zirconium) or precious metals (gold).

The vapor of transition metals is combined with reactive gases, determining the tone, resistance, and density of the coating, which has a thickness ranging from 0.2 to 1.5 µm. Gold deposition, on the other hand, is performed in an inert atmosphere to preserve the characteristics and purity of the metal; in this case, the film thickness typically ranges between 0.05 and 0.1 µm. Color modulation depends on parameters such as gas pressure, deposition energy, and the sequence of layers.

The elements that determine the final appearance include:

- the combination of film materials (TiN, ZrN, TiCN), which directly influences the tone

- the finish of the substrate, which can make the gold brighter or more satin without changing the composition of the film

Color stability is linked to the ceramic nature of nitrides, which do not oxidize easily and do not undergo significant variations with humidity or daily handling.

Yellow gold PVD: aesthetic result and uses

Yellow gold PVD is the most widespread variant. The color derives from the ratio between TiN and ZrN, a combination that makes it possible to achieve a bright and very uniform yellow. On polished surfaces, a particularly mirror-like effect is obtained, while a satin finish provides a softer and more elegant tone.

Yellow gold PVD is used in various sectors: eyewear, fashion hardware, watches, handles, and design objects. Chromatic repeatability combined with cost savings is one of the main reasons why many brands have adopted this technology for collections in which aesthetic consistency is essential.

Rose gold PVD: how it is achieved and when it is worth using

The rose gold PVD tone is obtained by introducing elements that shift the color toward pinkish variants, generally through multilayers based on TiN and TiCN. Carbon contributes to the pink hue by reducing the prominence of yellow, without introducing free copper on the surface.

The result is a stable, uniform pink tone that is resistant to color alterations. It is a highly appreciated solution for elegant jewelry, eyewear, and decorative small metal parts.

Gold PVD on steel: result and behavior

Steel is one of the most compatible substrates for PVD. Thanks to its mechanical stability and ability to withstand process temperatures, it allows for an adherent, uniform, and bright coating. The quality of the starting surface directly affects the result. Usually, in addition to mechanical preparation (satin finishing, polishing, etc.), no chemical process is required on the steel surface to ensure resistance to corrosion and oxidation of the processed part.

Gold PVD on steel is particularly widespread in eyewear, fashion accessories, and technical small parts. The combination of film hardness and substrate robustness ensures excellent durability over time.

Does gold PVD wear out? Durability, scratches, and maintenance

One of the most frequently asked questions online is “does gold PVD wear out?”.

In the case of simulated gold or gold-like PVD finishes, their use makes it possible to give greater longevity to the items on which they are applied. In fact, compared to gold, which is an extremely soft metal, these deposits based on metallic nitrides and carbonitrides tend not to become dull over time, maintaining the “mirror-like” effect for a long period.

In everyday practice, both for gold PVD and simulated gold PVD, the coating resists wear well, but it is not immune to scratches if subjected to constant contact with hard surfaces. Durability depends on film thickness, substrate preparation, and conditions of use.

There are three situations in which the film can be damaged:

- intense mechanical abrasion;

- coating thickness that is too low;

- substrate porosity or irregularities that compromise adhesion.

Under normal conditions of use, eyewear, fashion accessories, technical small parts, color and brightness are maintained for a long time. As a general rule, it is sufficient to avoid abrasive surfaces and clean the product with a soft cloth.

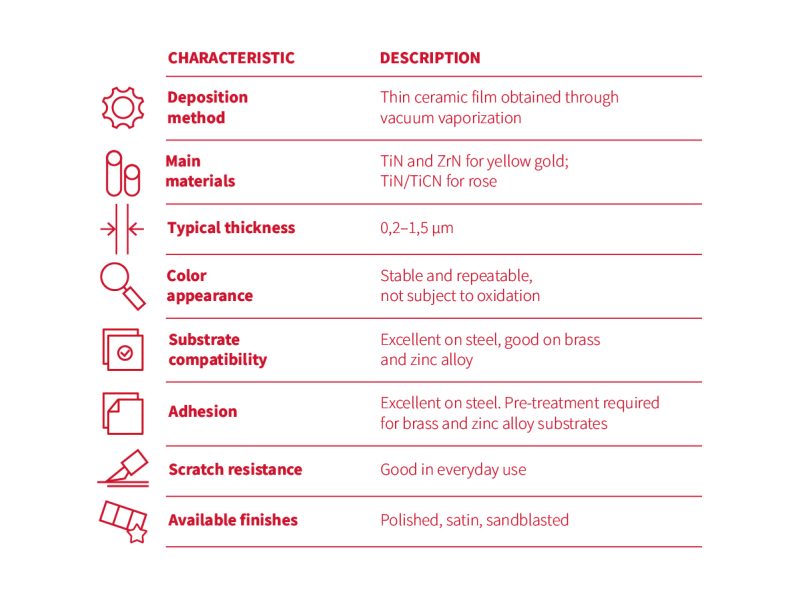

Main characteristics of gold PVD

FAQs

Is gold PVD real gold?

It depends on the required technical configuration. At LEM, we manage both processes: the deposition of ceramic films (simulated gold PVD) that reproduce the gold tone through the use of metallic nitrides, and the production of multilayer systems that integrate a final layer of real 24k gold.

Does gold PVD change color over time?

No, both nitrides and gold are stable and do not darken or change color over time.

Does gold PVD on steel last longer than on brass and zinc alloy?

Steel is a particularly compatible substrate with the process and does not require chemical pre-treatments. It does not provide particular advantages in terms of durability.

Conclusions

Gold PVD or simulated gold is a decorative treatment used to obtain surfaces with bright and uniform tones. The yellow and rose variants make it possible to adapt the color to different stylistic needs, while application on steel offers a good compromise between aesthetics and durability. Although not eternal, the gold finish maintains its properties for a long time, especially when deposition is carried out on properly prepared substrates and with suitable thicknesses.

Maximilian

Responsabile tecnico area PVD - LEM srl

Did you find the article interesting? Share it now.

© 2026 Lem Galvanica. All rights reserved

Did you find something interesting? Contact us now!

LEM technicians are ready to address any questions or concerns you may have.

Request more information and discover our tailor-made solutions.

Other articles you may be interested in

Water management and treatment in electroplating and PVD: what really happens behind the scenes

Wastewater treatment and recirculation in electroplating and PVD: technologies, green chemistry, and solutions to reduce waste, costs, and environmental impacts.

PVD (Physical Vapor Deposition): definition, operation and main applications

The PVD process, Physical Vapour Deposition. A technical overview of how it works, the materials involved, and its industrial applications.

Outsourcing PVD and Galvanic Treatments: Advantages, Risks, and Strategies in Industrial Subcontracting

Is it better to invest in an in-house galvanic or PVD system, or to rely on an external supplier? Let’s analyze the costs, regulatory risks, and benefits of outsourcing in the surface treatment industry, with real examples and a focus on the strategic role of specialized partners such as LEM.