Water management and treatment in electroplating and PVD: what really happens behind the scenes

Wastewater management in industrial plants

When people talk about surface treatments, they usually think about the final result: a shiny finish, a perfect color, a durable coating. What is rarely considered is how much water is needed to achieve all this, and, above all, what happens to that water after it has done its “job”.

In electroplating and PVD, water is not just a resource: it is an integral part of the process. And like any ingredient, it must be properly managed at the end of its use.

Today, companies must implement electroplating wastewater treatment processes not only to comply with regulations, but also because reducing waste benefits everyone: the environment, customers, and the company’s bottom line.

Why water used in electroplating is so difficult to treat

During the various stages of electroplating processes, water becomes enriched with different substances such as metals or salts, both organic and inorganic. In rinsing tanks, the solutions are diluted, while in spent baths the concentration of pollutants is much higher.

The result?

A mix of very different effluents that cannot be treated with a single technology. It’s a bit like trying to clean both a greasy pan and a limescale-covered tap with the same detergent: it doesn’t work. Each type of “dirt” requires a specific method.

Green chemistry: a smart way to reduce waste

Before even talking about treatment, companies can reduce the amount of “dirt” they produce. This is the core of green chemistry, an approach that is simple yet surprisingly effective.

It means making choices such as:

- using more environmentally friendly (eco-friendly) and more efficient substances

- designing racks and fixtures that improve performance and reduce drag-out from process tanks

- keeping all tank-side equipment under control through regular maintenance

In practice, everything that prevents waste before it even needs to be managed.

The cradle-to-cradle model adds an extra step: what is waste today can become a resource tomorrow. “Dirty” water is not necessarily lost. With the right technologies, it can be returned to the production cycle.

How LEM reduced consumption and waste in its water cycle

In recent years, LEM has introduced a series of improvements that have changed the way water resources are managed. Some of the most concrete actions include:

- new, more efficient treatment plants

- fixtures designed to reduce drag-out

- layouts that are studied upstream in the design phase to ensure the system is optimized from the start.

Why investing in a modern system pays off

A good electroplating wastewater treatment system is not only about regulatory compliance.

It helps save water, reduce the use of reagents, stabilize process baths, and improve treatment quality.

It reduces incidents and regulatory risks, improves overall production management, and delivers a tangible economic return.

At LEM, this approach has led to a significant reduction in water consumption and waste generation. Treatment is no longer a cost, but a value-generating element.

The technologies we use to treat water

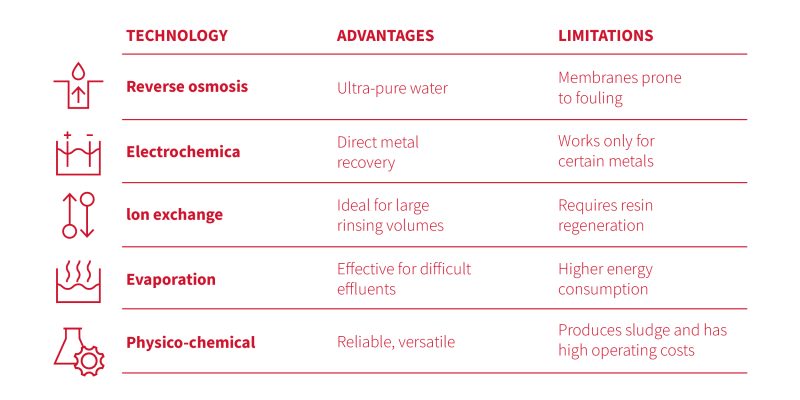

There is no one-size-fits-all solution. Each line has its own contaminants, flows, and constraints. LEM always combines at least two fundamental building blocks:

- a system that recirculates process water (reverse osmosis, ion exchange);

- a system that removes what cannot be recovered, such as physico-chemical treatment.

It is this combination that guarantees efficiency and final safety.

Technologies used by LEM for electroplating wastewater treatment

Reverse osmosis: the “super-advanced filter”

Reverse osmosis works like a highly selective filter. It allows only water to pass through and retains everything else.

Electrochemical recovery: turning waste into a resource

In some solutions, metals can be recovered. Electrochemical processes “bring them back” by depositing them in metallic form onto a support.

It is simpler than it sounds: the metal becomes solid again and can be reused. Less waste, lower costs, and fewer pollutants in the effluent.

Ion exchange: perfect for rinsing stages

Demineralizers operate continuously, capturing contaminants and releasing clean water that can be reused.

It is a very efficient technology, ideal for rinsing operations. It is used when volumes are high and the goal is to reduce water consumption and effluent generation without interrupting production.

Evaporation: when an extreme solution is needed

Evaporation comes into play with the most challenging effluents. Water evaporates, is cooled, and then condenses back into liquid form. What remains is a highly concentrated residue that is easier to manage.

It is not always the most economical solution, but in some cases it is the only one that works effectively.

Physico-chemical treatment: the classic method, still essential

Oxidation, neutralization, precipitation. This is the treatment that removes metals and complex substances in most cases.

It is a proven technology and still indispensable today to ensure compliant discharge.

Conclusions

Electroplating wastewater treatment is a complex topic, but it can be addressed with method and common sense. Reducing waste, recovering what can be recovered, and efficiently treating the rest is the winning strategy.

Mario

Responsabile area manutenzione impianti - LEM srl

Did you find the article interesting? Share it now.

© 2026 Lem Galvanica. All rights reserved

Did you find something interesting? Contact us now!

LEM technicians are ready to address any questions or concerns you may have.

Request more information and discover our tailor-made solutions.

Other articles you may be interested in

How a PVD System Works: Technologies and Processes Explained

Discover how a PVD coating system works: vacuum chamber structure, deposition technologies (Sputtering, Arc), and process control. An industrial guide for companies.

PVD and Electroplating: Current Trends and Future Scenarios for Metal Finishes

Discover the latest metal finishes: matte black, gun metal, golds, and bronzes. Trends in PVD and electroplating for fashion, design, and contract sectors.

Gold PVD: characteristics, performance and tones of the surface treatment

Gold PVD: durability, colors, rose gold and yellow gold, use on steel and why it does not wear easily. Complete guide to gold PVD treatments.