PVD (Physical Vapor Deposition): definition, operation and main applications

What’s PVD?

PVD, short for Physical Vapour Deposition, is a process used to apply thin metallic or ceramic coatings onto metal or plastic substrates.

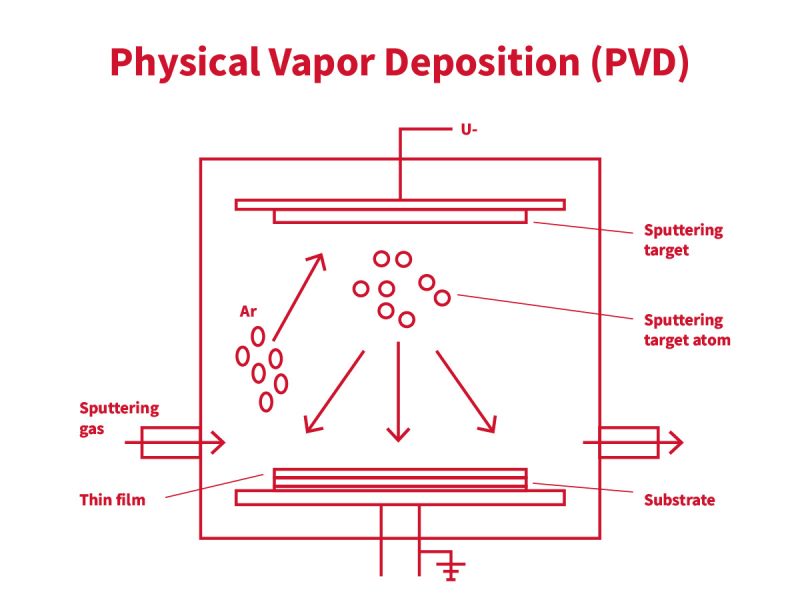

It takes place inside a vacuum chamber, where the coating material is vaporized from a solid source and transferred in atomic or molecular form to the surface of the component, where it condenses into a compact, highly adherent film.

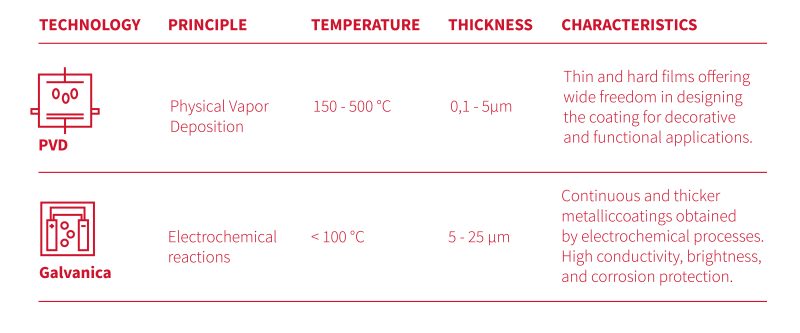

Unlike electroplating processes, based on chemical reactions in electrolytic solutions, PVD relies exclusively on physical phenomena of evaporation and ionization. The result is a pure coating with precisely controlled thickness (0.1–5 µm), free from chemical waste and characterized by high hardness, resistance, and long-term colour stability.

How PVD Works

The PVD process is carried out inside a vacuum chamber at pressures between 10⁻³ and 10⁻⁶ mbar. The coating material (the “target”), typically titanium, zirconium, chromium, or aluminium, is heated or bombarded with high-energy ions. The released atoms or ions travel toward the substrate and condense to form a thin, highly adherent film.

During Physical Vapour Deposition, process parameters, temperature, pressure, bias voltage, and process atmosphere (argon, nitrogen, oxygen, acetylene), influence hardness, colour, resistance, and film uniformity. Proper control of these settings ensures consistent, repeatable coatings suitable for both technical and decorative applications.

Main PVD Technologies

PVD technologies differ based on how the material is converted into vapour:

- Thermal Evaporation: the target is heated until it evaporates (Joule effect or electron beam). Suitable for heat-sensitive substrates and thin decorative coatings.

- Magnetron Sputtering: a plasma of inert gas strikes the target with accelerated ions, releasing atoms that deposit on the part. Produces dense, uniform films, even on complex geometries.

- Cathodic Arc Evaporation : an electric arc locally vaporizes the metal. Delivers very hard, highly adherent PVD coatings, ideal for tools and mechanical components.

A PVD system may integrate multiple sources to combine productivity and versatility. The choice of technology depends on the substrate, desired thickness, and required performance.

Materials Used in PVD Coatings

PVD coatings use metals and reactive gases to create high-performance compounds:

- Pure Metals (Ti, Zr, Cr, Al, Au…): properties vary depending on the metal; PVD coatings are typically harder than the bulk metal.

- Metal Nitrides (TiN, ZrN, CrN): high hardness; gold or metallic-grey colour tones.

- Carbides & Carbon-based Coatings (TiC, CrC, TiC/C, CrC/C): hardness ranges from moderate to very high depending on conditions. Colours range from grey to deep black.

- Carbonitrides (TiCN, ZrCN, TiAlCN): very high hardness; tones from amber-yellow to light bronze, pinkish, or violet.

- Oxides (TiO₂, ZrO₂): used for interference coatings with iridescent optical effects.

The ability to modulate chemical composition allows tailored PVD films in terms of colour, gloss, and durability. These features make PVD ideal for faucets, eyewear, furniture, fashion, and precision mechanics.

Properties of PVD Coatings

PVD films offer superior technical performance compared to traditional coatings:

- Thin layers that preserve assembly tolerances

- Surface hardness >800 HV / up to 2000 HV for technical coatings

- High resistance to corrosion and oxidation

- Long-term colour stability and gloss retention

- Thermal compatibility with common metals and alloys

- Uniformity and repeatability even on complex geometries

Industrial Applications of PVD

Thanks to the balance between aesthetics and performance, PVD is used widely across industries:

- Bathroom fittings and tapware: uniform, durable finishes

- Eyewear and fashion accessories: lightweight, elegant coatings

- Automotive: protection and visual enhancement of components

- Tooling and precision mechanics: higher hardness and tool life

- Furniture and interior design: highly uniform metallized surfaces

PVD Systems and Process Control

A PVD system includes a vacuum chamber, pumping units, plasma sources, and electronic controls for temperature, pressure, and voltage. Modern systems feature:

- Real-time monitoring of all process parameters

- Multiple sources for multilayer coatings

- Automated software for cycle management

Accurate control ensures uniform thickness and stable adhesion. Industrial setups also include plasma pretreatments and optical inspection systems for final quality checks. See also: PVD Division.

Comparison Between PVD and Other Coating Technologies

PVD offers an alternative to electroplating, eliminating hazardous chemicals and reducing waste and water consumption. It is the most advanced solution for durable protective finishes, with an excellent balance of performance and aesthetics. Learn more: PVD Treatments.

Advantages and Technical Limits of PVD

Main Advantages

- High mechanical and chemical resistance

- Wide colour range and customizable metallic finishes

- Compatibility with various substrates

- No liquid waste generation

- High repeatability and parameter control

Limits

- Uniformity may be challenging on complex shapes

- High equipment cost

- Longer cycle times compared to electroplating

Despite these limitations, PVD is now the reference technology for high-performance coatings focused on durability and appearance.

Related Terminology

- Target: starting material for the coating

- Substrate: surface being coated

- Plasma: ionized gas enabling deposition

- Sputtering: ion bombardment of the target

- Thermal Evaporation: direct heating vaporization

- Cathodic Arc Evaporation: arc-based vaporization

- Vacuum Chamber: sealed, contamination-free environment

- Bias: electrical potential applied to substrates

- Thin Film: compact layer with micron-level thickness

References and Technical Standards

- ISO 26423:2016 – film thickness measurement (Kalotest)

- ISO 9227:2017 – corrosion resistance (salt spray test)

- ISO 14577-1:2015 – hardness measurement (nanoindentation)

The adoption of international standards ensures quality and traceability of PVD coatings, guaranteeing stable performance and compliance across advanced industrial sectors.

Maximilian

Responsabile tecnico area PVD - LEM srl

Did you find the article interesting? Share it now.

© 2026 Lem Galvanica. All rights reserved

Did you find something interesting? Contact us now!

LEM technicians are ready to address any questions or concerns you may have.

Request more information and discover our tailor-made solutions.

Other articles you may be interested in

How a PVD System Works: Technologies and Processes Explained

Discover how a PVD coating system works: vacuum chamber structure, deposition technologies (Sputtering, Arc), and process control. An industrial guide for companies.

PVD and Electroplating: Current Trends and Future Scenarios for Metal Finishes

Discover the latest metal finishes: matte black, gun metal, golds, and bronzes. Trends in PVD and electroplating for fashion, design, and contract sectors.

Gold PVD: characteristics, performance and tones of the surface treatment

Gold PVD: durability, colors, rose gold and yellow gold, use on steel and why it does not wear easily. Complete guide to gold PVD treatments.