Our company

LEM is an industrial company specialized in advanced surface treatments, including PVD and galvanic, designed for high-end sectors such as luxury, fashion, and design. With a strong focus on technological innovation and sustainability, the company has built a solid reputation through the high quality of its products and its commitment to environmental responsibility. To learn more, visit our dedicated page.

Our way of doing business

LEM takes a responsible approach at every production stage, ensuring quality, safety, and environmental respect. Our commitment to sustainability is reflected in the numerous certifications we have obtained, including ISO 14001 for environmental management and SA8000 for social responsibility. Discover what it means to do business the LEM way.

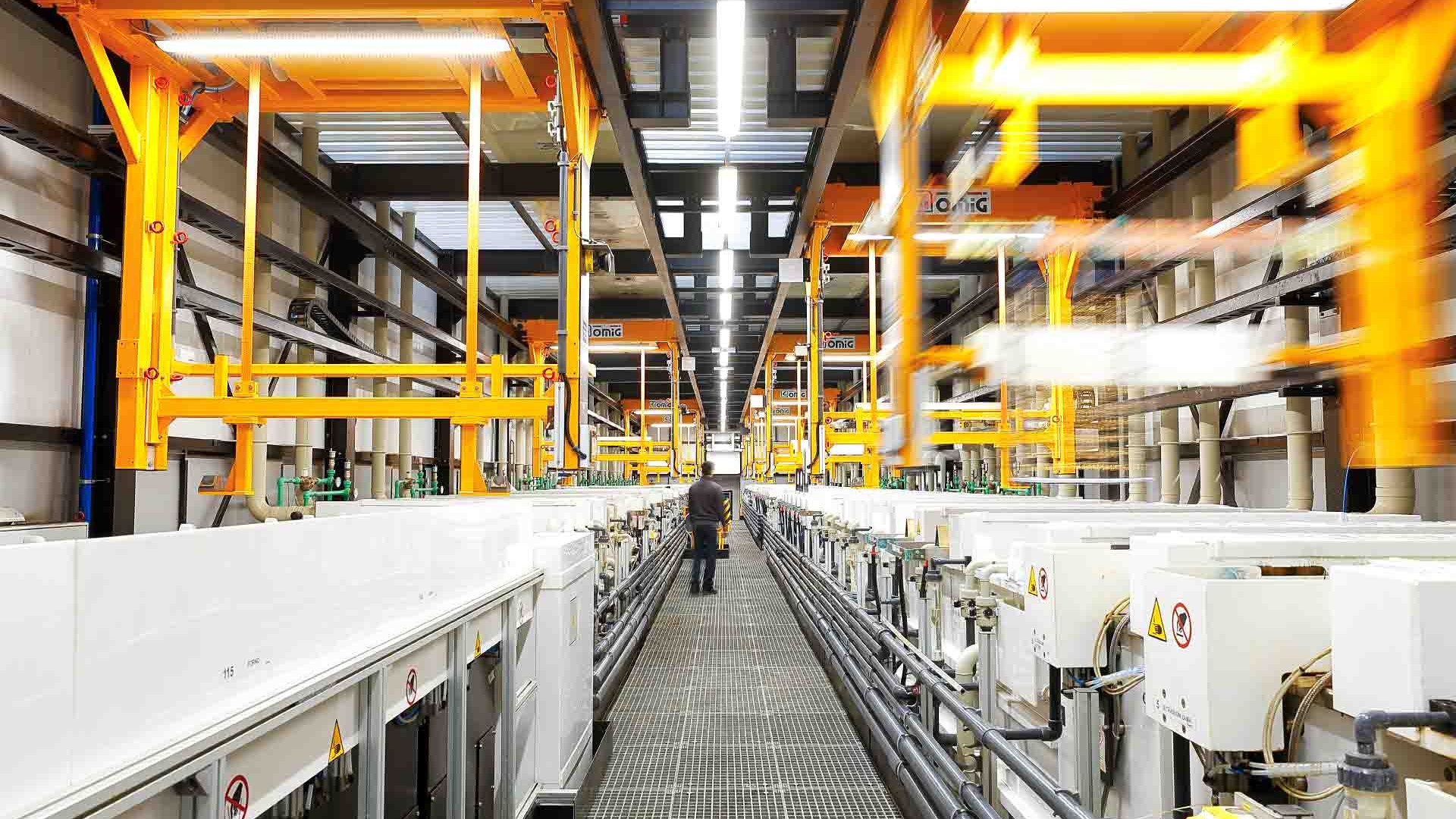

LEM production process

Discover LEM’s production model, our exclusive system that ensures exceptional results, consistency, and punctuality from industrialization to delivery. LEM model’s four distinctive phases enhance the perceived quality of your products, adding value at every stage. Learn more about each phase and how it can turn your product into a recognized success.